Elevating Your Excavation Projects with Quality Final Drive Motors

In the world of heavy machinery, excavators play a pivotal role in various industries including construction, mining, and landscaping. At the heart of these powerful machines lies the final drive motor, an essential component that transforms hydraulic energy into the formidable force required to move and operate the excavator. As a leading final drive motors for excavators supplier, Shop Hydraulic America is committed to providing high-quality, reliable final drive motors that empower your excavation projects.

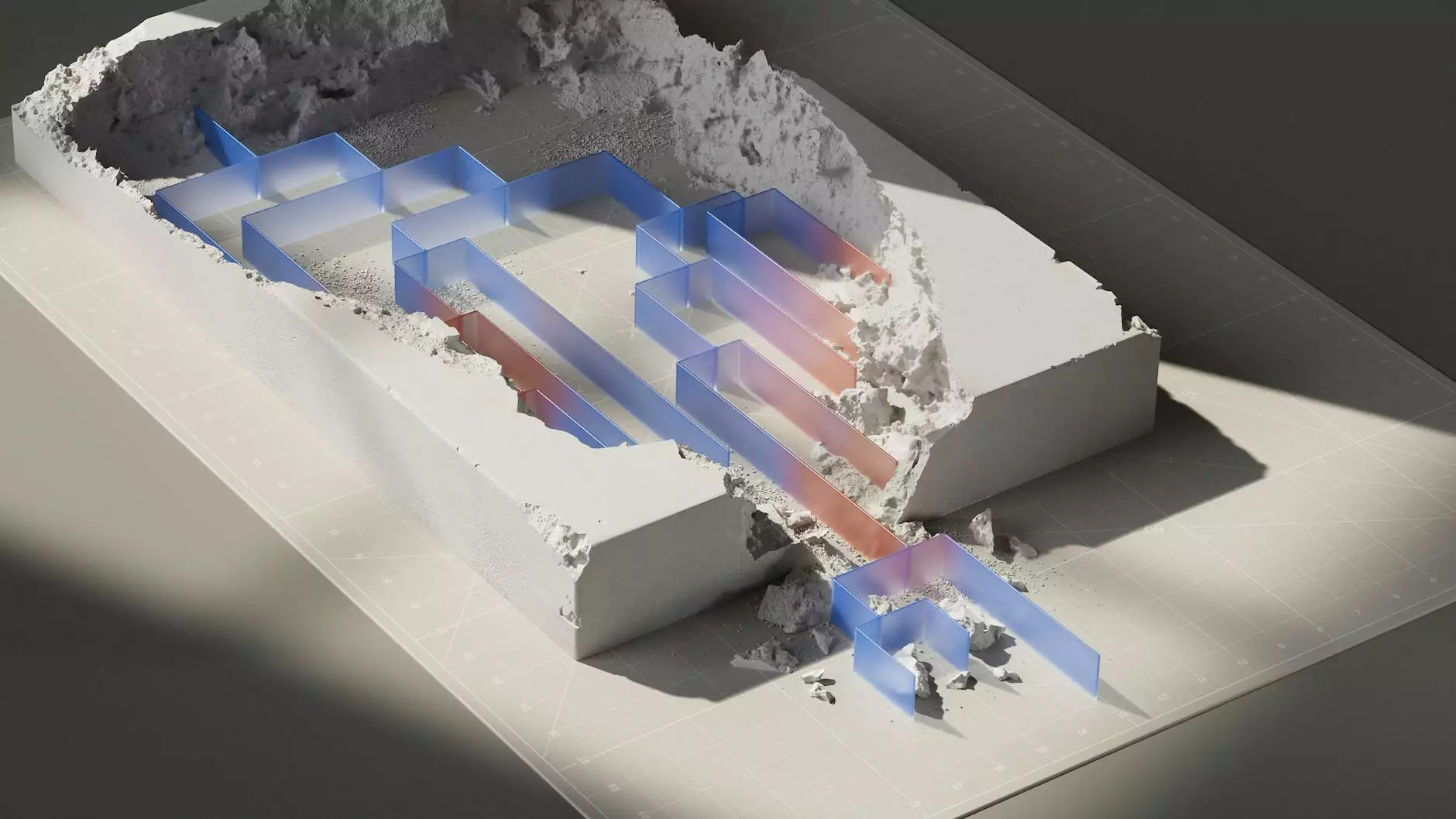

Understanding Final Drive Motors

Final drive motors are crucial transmission systems converting hydraulic pressure into motion. They allow excavators to perform various tasks with maximum efficiency and precision. Understanding how these components operate can help operators and managers make informed decisions when maintaining or replacing parts.

Components of a Final Drive Motor

Every final drive motor consists of several integral parts:

- Hydraulic Pump: Responsible for generating hydraulic pressure.

- Gear Reduction: Reduces the speed and increases the torque, allowing for greater power delivery.

- Planetary Gear Set: Provides smooth transmission of power and speed.

- Output Shaft: Transmits the final rotational motion to the tracks of the excavator.

Why Quality Matters: Choosing the Right Final Drive Motor

When it comes to selecting final drive motors for excavators, quality is of utmost importance. Investing in less reliable options can lead to frequent breakdowns, costly repairs, and reduced efficiency. Here’s why you should consider Shop Hydraulic America for your final drive motor needs:

Durability and Performance

Our final drive motors are engineered for strength and longevity. They undergo rigorous testing to ensure they can withstand the tough conditions of excavation work. Key features include:

- High-quality materials that resist wear and tear

- Advanced engineering that promotes efficient operation

- Tailored designs to fit an array of excavator models

Expert Support and Guidance

At Shop Hydraulic America, we pride ourselves on providing exceptional customer service. Our team of experts is available to help you choose the best final drive motor for your specific excavator model, ensuring compatibility and optimal performance.

Cost-Effectiveness

Choosing high-quality final drive motors can lead to long-term savings. Consider the potential cost of down-time due to malfunctions and repairs. By selecting reliable components from Shop Hydraulic America, you minimize these risks and maintain productivity.

Applications of Final Drive Motors in Excavators

Final drive motors are versatile and can be utilized in various applications within excavators. Here are some common uses:

- Construction Projects: Used for digging, grading, and demolition tasks.

- Mining Operations: Essential for transporting materials, excavating ore, and site preparation.

- Landscaping: Facilitate earth-moving tasks, creating slopes, and digging out foundations.

How to Maintain Your Excavator’s Final Drive Motors

Proper maintenance of your excavator’s final drive motors is crucial for extending their lifespan and improving performance. Here are some tips for maintaining your equipment:

Regular Inspections

Frequent checks help identify potential issues before they escalate. Look for:

- Fluid leaks

- Unusual noises during operation

- Excessive heat buildup

Fluid Replacement

Hydraulic fluids degrade over time. Adhere to the manufacturer’s recommendations for fluid replacement to prevent damage and ensure optimal performance.

Professional Servicing

Schedule routine servicing with certified professionals to maintain and calibrate your final drive motors, ensuring they work at peak efficiency.

Frequently Asked Questions About Final Drive Motors

What is the lifespan of a final drive motor?

The lifespan varies depending on usage, maintenance, and model. However, with proper care, our final drive motors often last several years, even under heavy use.

Can I replace the final drive motor myself?

While it's possible for those with mechanical expertise, we recommend professional installation to prevent issues and ensure proper function.

What should I do if my final drive motor fails?

First, stop operating the excavator. Contact our customer service team for guidance on diagnosis and replacement options.

Why Shop Hydraulic America is Your Best Choice

At Shop Hydraulic America, we understand the importance of having reliable equipment in the field. Our commitment to quality products, customer satisfaction, and expert support positions us as the premier final drive motors for excavators supplier. Our comprehensive range of products coupled with dedicated service ensures that you receive the best possible support for your projects.

Conclusion

In conclusion, investing in high-quality final drive motors for excavators is vital for ensuring efficiency, durability, and overall productivity in your operations. With Shop Hydraulic America, you can trust that you are receiving the best products available on the market, backed by expert knowledge and customer service. Elevate your excavation capabilities and make a significant impact on your projects today!

Contact Us

Ready to find the perfect final drive motor for your excavator? Visit our website, shophydraulicamerica.com, or contact our knowledgeable team to explore our extensive range of products and receive personalized assistance. Let us help you drive your projects to success!